What is ozonation, and why is it used?

- February 16, 2024 |

Ozone (O3) occurs in nature and can also be formed from oxygen, or oxygen compounds, in a variety of ways. Ozone is a powerful oxidant widely used in water treatment to kill bacteria and other organisms, and reduce taste, odors, and color. The inherent features of ozone are its high oxidation potential and disinfection capabilities. This, coupled with the fact that ozone decomposes to oxygen, and produces fewer disinfection by-products than chlorine, makes it an ideal choice for many water treatment applications.

Following years of treatment challenges attempting to control low-level tastes and odors in the Rogue River source, ozone emerged as the most promising treatment option, being highly successful at eliminating taste and odor causing compounds, while also providing other treatment benefits. Ozonation was added at the Robert A. Duff Water Treatment Plant in 2002. An overview of the process follows:

Storage and Vaporization

Oxygen is delivered to the treatment plant as liquid oxygen (LOX), where it is stored on site in an insulated pressure container. As the LOX is used, it passes through an ambient vaporizer where it is converted to gaseous oxygen (GOX). The oxygen is very clean and dry with a dew point of less than –95oC.

Ozone Generation

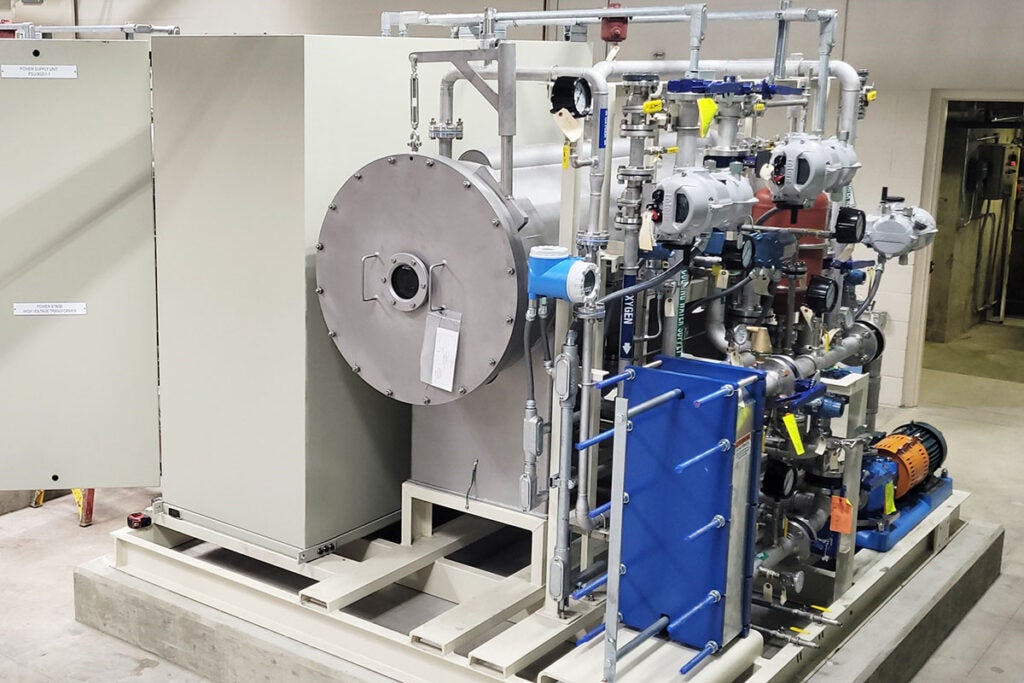

The GOX flows to the ozone generators for ozone production. Oxygen molecules (O2) travel through a discharge gap, which is around the devices called dielectrics, where they are subject to a high voltage corona discharge. Delivering high voltage to the dielectrics produces this discharge. While in the gap, some of the O2 molecules are separated into free oxygen atoms (O). It is these free oxygen atoms which combine with other O2 molecules to form ozone (O3).

Since this process does not convert all the oxygen molecules into ozone, the gas leaving the ozone generator contains only 10-12 percent. This percentage is a function of inlet gas flow rate, temperature, pressure, and power input to the ozone generator.

Heat accumulated by the ozone generation process is removed by cooling water. Cooling water passes around the cylindrical tubes, which house the dielectrics. This cooling process is crucial to the efficiency of ozone production since heat is a detriment to the formation of ozone.

Dissolution

The mixture of ozone and oxygen gas is carried to injection points on a side-stream flow of the raw water and then combined with the balance of the raw water as it enters the ozone contact basin.

The ozone is in contact with the water as it travels through the ozone contact basin and is consumed rapidly. Ozone has a measurable residual in the first chambers of the basin but by the time the water gets to the end the ozone residual is gone.

Ozone Destruction

There is a small portion of the ozone that does not go into solution and therefore reaches the headspace of the closed ozone contact basin. This ozone is drawn off by vacuum and passes through an ozone destruct catalyst, which converts the ozone back to oxygen, which is discharged.